June 14, 2016

Recently, XCMG participated in Technical Product Documentation Standardization Committee of the International Organization for Standardization (ISO/TC10) conference in Berlin. After careful preparation and intense discussion, the XCMG-proposed General Requirements for Mechanical Products Digitization Manual was officially approved and allowed to establish a work group with the international standard number of ISO 21600. The XCMG-led Metal Component Dimensioning, and participated Spline and Spline Teeth Representation and Requirements for Mechanical Product Digital Model Virtual Assembly have all successfully proceeded with the next stage.

If we compare the world market to a playing area, the standard is the technical rules. Primary players only obey someone else's rules and depend on mercies, while senior players participate or dominate the formulation of rules, and reap the competitive advantage. XCMG also experiences this transformation in its internationalization journey.

As an important part of the internationalization strategy, XCMG’s standardization work also embarked on a global stage. Marked by the formulation of a series of international standards, XCMG has entered into a new era of competition from product technology to strategic transformation and upgrading.

To implement the internationalization strategy, XCMG took part in the German Institute for Standardization (DIN) standards meeting. Stepping into the DIN headquarters building, people will feel the increasingly intense standardization culture. On the well lid in the street, DIN standard numbers were engraved. Outside the DIN headquarters building, the statuses of two German standard founders in 19th century stood erect. Stepping into the DIN headquarters building, slogans like “standards and norms ensure your safety” and “standards make the work more efficient” were hanged along the long corridor. These made people feel that developed countries like Germany are pushing the standardization undertakings with strategic vision and spirit of craftsmen. In the contact with foreign experts, we also feel their rigorous attitude.

XCMG's main task in the meeting was to promote the approval of General Requirements for Mechanical Products Digitization Manual and set up a work group. Extensively involved in international standards activities, XCMG was aware of the absence of international standard in the field of digitalization. From 2014 it began to design this standard. Before submitting a formal proposal, it researched a large number of international standards and translated some key parts. With the full understanding of external technology, XCMG, with its own research results in digitization, prepared a detailed draft. The draft was preliminarily approved, while for official approval, it still needs to take another two steps: ISO/TC10 experts’ feedback on the scope of the standard and the ISO and IEC Joint Working Group JWG16’s feedback on the content of the standard.

Because the feedback of the joint work group was obtained on the eve of the meeting, XCMG’s staffs worked day and night to review the scope of the standard and the feedbacks from experts. At the ISO/TC10 meeting, staffs and foreign experts debated fiercely. Even during the break of the meeting, they seized the opportunity to explain to experts XCMG’s understanding of digital manual technology. Finally, foreign experts agreed with the standard positioning and allowed to establish a work group. In the coordination meeting, XCMG’s staff and JWG16 experts again had a deep discussion. Listening to the opinion of the other side, we patiently explained the difference of the standard with other standards, and demonstrated the independence of this standard from basic technology, work evolution and Standardization Committee scope, successfully making the project reserved under the ISO/TC10/SC6 Mechanical Products Committee.

The approval greatly encouraged XCMG staffs, and other projects also welcomed news of victories. The XCMG-led Metal Component Dimensioning has solved the technological problem in the CD phase, entered into the DIS phase, and seen the dawn of successful release.

Standard first has never been an empty talk. In the “Made in China 2025” plan, the national intelligent manufacturing standard system was clarified, while the development of digital technology standards would be the most basic and most important part. Recently, the General Requirements for Mechanical Products Digitization Manual was officially approved by the International Organization for Standardization and was allowed to set up a work group ISO/TC10/SC6 WG19. This was XCMG’s demonstration of strength on international stage on behalf of China’s equipment manufacturing industry. Also, it showed XCMG’s fruitful achievements in the digitalization development. With customer-oriented service, XCMG has made a lot of efforts in the market service. XCMG’s efforts in service (digital) technology have led to an international standard representing the highest level of the industry in the world.

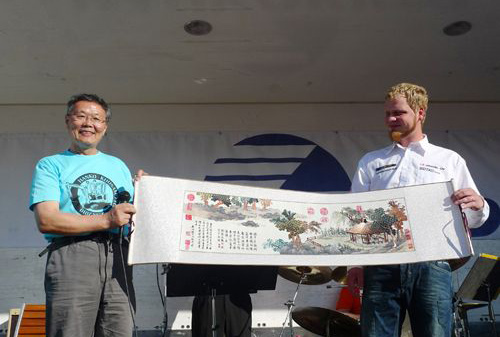

What is worth more celebration was that in the process, XCMG has cultivated a number of international standards personnel with comprehensive quality. They are familiar with international standard formulation rules and international standard system. Their excellent technical ability enabled them to communicate with top international experts from Siemens and Schaeffler. With these projects and personnel, XCMG will surely be able to make greater achievements in the work of international standardization and better support the company's internationalization and transformation and upgrading, thus spreading the pursuit of excellence on technical standards, product technology and services throughout the world.

At 6:00 pm on 29th June, a SWE17B excavator with provisional license plate appeared, the waiting cro

May 29 ~ June 2, the M&T EXPO was held at Immigrants Exhibition Center in St. Paul, Brazil. During the exhibition, Shandong Lingong exh

On November 7, the opening ceremony for Phase III Training of XCMG Public Welfare Project -- "Global Excellent Operator" was held in XCMG, where Li Ge, the Deputy Secreta

What is breaking force deficiency? It is when you press the brake pedal down, the loader does not slow down or stop as required. The main causes include: ① The brake system i

Copyright Notice 2002-2026 global-ce.com Construction Machinery Online. All rights reserved.

Address: Room 901, Building C, Ruipu Mansion, Hongjunying South Road No.15, Chaoyang District, Beijing.100107 P.R.China