November 24, 2016

As top engineering machinery event, “bauma China” (International Trade Fair for Construction Machinery, Building Material Machines, Mining Machines and Construction Vehicles) not only shows the world in Chinese market products researched and developed based on Chinese client experience but also tells the world that we are shouldering the responsibility of pushing future development with technology, wisdom and inventiveness. In this arena where global construction machinery giants rivals with each other, XCMG, as leader of new industrial development directions and trends in all previous fairs, also gives its declaration formally --- “Inventiveness, intelligent manufacturing for you”. To better interpret the subject, except organizing amazing main frame cluster show, XCMG also debuts the family of core parts and components --- “invisible champion” among machinery equipment.

Intelligent, energy-saving and performance are the engine core parts and components of XCMG adopt to break high end pattern under new normal. “Construction machinery industry of China solves 90% of issues. The key is to conquer the last 10%. It is just like climbing the last few hundred meters to Mount Everest. It needs more power, more money, more wisdom and more talent.” Like “Climbing Mount Everest Theory” proposed by President & Secretary of Party Committee Wang Min, XCMG has begun to lay out “inventive” chess for core parts and components earlier. Among them, XCMG Hydraulics Co., Ltd., a part & component enterprise established in 1975, depends on no other things than forty years devoted work to play chess and make hydraulic elements of XCMG present all over China, even be exported in batches to almost more than 20 countries and areas such as Europe, America, Russia and Japan based on research and development of high-end products featured by intelligence, energy saving and performance, shine among main frames of global various construction machinery, environment sanitation machinery, mining machinery, ship equipment and the like and finally become “invisible champion” leading the development of independent core part and component industry.

“Valve” products break through high-end product pattern with “intelligence”

As concept of “intelligent manufacturing” awakens, automatic and digital intelligent technologies are being massively applied to manufacturing industry, which not only further guarantees quality stableness of products and improves operation efficiency but also opens a new road for product similarity elimination and brand value expansion. By sharply grasping the opportunity, core parts and components of XCMG focus their research and development on high-end hydraulic element manufacturing field. As XCMG acquired two European enterprises --- AMCA from the Netherlands and FT from Germany, plus establishment of European Research Center of XCMG, a “globally coordinating + independently innovative” R&D ecosphere of a full family of hydraulic elements is taking shape.

After being dedusted for 15 seconds in air shower, you enter into a close-type constant-temperature workshop. Although rolling of machines echoes in ears, look around, and not so many operation personnel may be seen, because it is provided with highly automatic production level. Superior processing equipment replaces majority of personnel. Several workers on the site either polish products under flashlights or hold testing equipment carefully to “diagnose” products like doctors…All of sudden, it feels like they are not manufacturing industrial products but carving artwork. This is hydraulic element production line of XCMG Hydraulics Co., Ltd. Various hydraulic valves showcased in the fair were born on this production line.

In order to achieve all-around breakthrough in hydraulic field, in 2012, XCMG took actions and acquired two European renowned hydraulic manufacturers --- FT from Germany and AMACA from the Netherlands; at the same time, XCMG also invested 360 million euro to set up a European R&D center in Germany and focus on core elements and key technologies such as hydraulic valve, pump, motor and intelligent control. Under this strong layout, XCMG Hydraulics formed a closed globally-coordinated, mutually linked and mutually supported cooperation relationship with FT from Germany, AMACA from the Netherlands, European Research Institute and the like so as to exert strong fighting strength in conquering high-end core hydraulic parts and components. In this fair, electric rotary cushion valve is the result achieved in this research and development ecosphere.

As an experienced engineer in European R&D Center, Doctor Fei Kaoyin, to solve swinging action of cranes, joined in “CES Optimization” Project which specially aimed to improve operability, energy-saving performance and stableness. How to update the cushion action? Doctor Fei Kaoyin once organized vision conference for several times. To maturely substitute existing hydraulic proposal with electric control proposal, he argued fiercely with his colleagues. In the end, there emerged global first active buffer function which utilized electric proportional relief valve to realize swinging action of cranes. Novel electric rotary cushion valve is more stable and smooth during swinging action, which further stably improves new breakthrough in products and technologies of XCMG.

Such coordinated research and development scene is all over various hydraulic valve product families of XCMG. In 8 days, five valves are processed, two sets are assembled and one set is experimented…This is current research and development ability of CES team for hydraulic valves of XCMG. The project is led by European Research Center of XCMG and is supported by XCMG Heavy Machinery, XCMG Hydraulics and XCMG Institute. Four-arty coordinated research and development is realized for the first time so that hydraulic valves of XCMG are significantly improved in product parameters, such as cost, weight and response time, and performance indicators, such as control, intelligence and action stableness. In the booth for core parts and components of XCMG, various products invariably tell you that hydraulic valves of XCMG which outshine with their “intelligence” have become a “new trump” with which “complete hydraulic system solution provider” is able to go global, such as APVM loaded sensitive multiple unit valve and manual change valve which are developed specially for global renowned shop manufacturers and are able to resist 250,000 impact tests and 20,000 commutation tests, XSV loaded sensitive multiple unit valve of which trouble-free reversing impact exceeds 1,000,000 times and European and intelligently-manufactured-in-China APV multiple unit valve.

Build “green pass” with “energy conservation”

Equipment manufacturing is the basis of national economic development as well as important guarantee of industrial update and technological improvement of various industries. In recent years, our machinery manufacturing industry has risen strikingly, industrial system has been constantly improving and perfecting and technology innovation has been enhanced notably. However, ensuing energy consumption and pollution are more and more outstanding. In particular, adaption to requirements of environment and ecological development should be taken into consideration for design and manufacturing of main frames of construction machinery, and it goes trendy to research and develop environment-friendly products. Thus it is bound to apply part and component technologies that are more efficient and energy-saving. As a first-class domestic part and component enterprise, XCMG Hydraulics is committed to speeding up product research and development steps, applying light weight technologies to updates of hydraulic elements and striving to offer clients more efficient and energy-saving hydraulic system solution and technology support.

“As light-weight competitive product we took several years to create, it is bound to further boost overall performance improvement of fire engines. In the future, we will also launch the third generation and the fourth general light weight products so as to bring more ideal energy consumption performance.” This light weight competitive product mentioned by Chief Designer Zhang Qingkou for products of XCMG Hydraulics is the aluminum telescopic pipe debuting in this bauma fair. It is the first case in China. When such product was delivered for the first time, all clients were impressed by light weight technology without exception which makes it able to be held by one hand. High strength aluminum alloy is adopted for main part of such product of which weight is 2/3 lesser than regular stainless steel pipes. Besides, special surface processing technology and support-oriented technology are also applied. Thus, this product is provided with higher wear property and surface hardness, its inclined loading capability is improved, and service life is enhanced. Furthermore, it not only reduces power consumption of main frame but is also lighter and more flexible, thus totally ridding status quo where domestic fire engines need to rely on imported aluminum alloy pipe.

Application of part and component light weight technology is critical to energy conservation performance of main frame. As far as we know, all hydraulic cylinder products, such as various cranes, loaders and pump trucks, are novel energy-saving products specially designed and manufactured based on inheritance of previous research and manufacturing experience and construction characteristics of main frame. By constantly reinforcing structure optimization and analysis of light weight application, the company uses high-strength novel materials to replace traditional cylinder materials so as to make products be provided with good mechanical and technical performance. Therefore, compared with regular products, weight of a complete cylinder is 20% less or above. The company is leading future development direction of light weight products.

In the meantime, remanufacturing technology exhibited in part and component booth is also critical to building “green pass”, such as high velocity oxy-fuel and plasma electrolyte polishing. Right now, remanufacturing industry is gradually evolving into a new channel which construction machinery industry is actively exploring and trying as well as one of key technologies which section of core parts and components of XCMG adopts to develop remaining values of products to the most extent. In order to fully realize value rebirth of products, the company set up specially a remanufacturing branch to focus on research of hydraulic cylinder remanufacturing and key maintenance repair technologies and form a remanufacturing business frame and a technology research system. With lots of remanufacturing know-how breakthroughs and promotion application results, bid winning of large-tonnage remanufacturing projects of large-scale steel companies and achievements of orders for maintenance of American imported cylinders, it is proved conclusively that the post-market has become another business breakthrough rising point of the company.

See performance from “chip”, 8000 hours “indestructible” service life

As construction machinery is always operated outside and challenged by severe conditions such as sand storm and moisture, it more depends on reliability of products. In other words, no matter which trend industrial technologies are developing to, stableness and reliability of products must always be our first concept we should adhere to. This is also the first subject jointly faced by construction machinery manufacturers and their supporting part suppliers. As golden standard of “advanced technology, indestructible” was issued, XCMG also brought up goals of retargeting and refocusing on key core technologies and core parts and components. As leading hydraulic cylinder manufacturer, XCMG Hydraulics submitted a satisfying paper to this standard with 8000 hours “indestructible” performance.

“Bang---“ When excavators roared, one construction site in Pilbara area of Australia was buzzing again. In this mining area, close to equator and hot and dry, and of which outdoor temperature is always higher than 37°, a super-large-tonnage excavator has consecutively conducted 8000 fault-free operation for 8000 hours. Such result is attributable to light of hydraulic products of XCMG glittering inside. “Fault-free service time of hydraulic cylinders of China even cannot be realized by some international first-class products. Parts and components of XCMG are ‘gems’ we dug out in China!” Speech of this equipment director of this Australian mining area mirrors their trust in hydraulic cylinder products of XCMG. “Gem” he talked about is hydraulic cylinder of excavator displayed in the booth of core parts and components of XCMG. For a long time, because of high research and development difficulty and complicated processing technique, plus adverse working conditions of main frame, excavator has high requirements for cushioning and airtightness. Therefore, such products are regarded as “crown” among hydraulic cylinders and each update is under the spotlight. Boom cylinder of super-large-tonnage excavators exhibited this time is domestic largest-tonnage excavator cylinder researched and manufactured by XCMG Hydraulics in consideration of existing technology basis and equipment ability. As an internationally main competitive product of core parts and components of XCMG, application of a series of new materials, new technologies and new techniques not only breaks through cylinder technology bottleneck of domestic super-large-scale excavator but also wins wide compliment of main frame users at home or abroad. It once again gives the best interpretation to product concept of “advanced technology, indestructible”.

In addition, there are also some strange-looking “iron products” in the booth which also offer strong support to “inventive” chess of “invisible champion”: it is composed of three similar-looking cylinders, and , nicknamed as “triplet”, is a special three-cylinder sequential telescopic device; based on hoisting characteristics of multiple-stage telescopic jibs of lorry-mounted crane, the product, through three-cylinder overlapping placement, not only significantly improves the hoisting ability of main frame but also spurs structure optimization and technology update of main frame of lorry-mounted crane; medium self-locking, end-self-locking and whole-process-self-locking cylinder finally completed through 28 proposal improvements and tests effectively satisfy chassis steering needs of construction machinery, realize technological breakthrough in many aspects such as testing accuracy, response speed and service life of locking parts and fill in the gap between such domestic elements and imported products in service life and reliability generated for the past many years; various technical samples showing surface processing technology, welding technology and raw material technology give strong support to stableness and reliability of core parts and components of XCMG, which enables basic technique research to reach the level of “indestructible”.

“Further explore hydraulic field with technology innovation, win international competition with superior service.” Although adjustment labor brought by new normal of Chinese economy still continues, core parts and components of XCMG equipped with “strong support” has triggered the inventiveness return long time ago. As a leader for high-end core parts and components of China, “invisible champion” of XCMG is bound to “reach the top of Mount Everest”, win this high-end breakthrough “inventiveness chess” and freshly start from bauma China 2016 to advance towards the world from here and unleash vigorous vitality of “Made in China”!

Explanation of Multi-stage Sequential Cylinder

Hot High-end Hydraulic Valve Exhibits

Advanced Technique Exhibition

Complete System Exhibition

Cylinder of Domestic Largest-tonnage Excavator

Safe Locking Structure of Hydraulic Cylinder

Dump Truck System

Hydraulic Valve

At 6:00 pm on 29th June, a SWE17B excavator with provisional license plate appeared, the waiting cro

May 29 ~ June 2, the M&T EXPO was held at Immigrants Exhibition Center in St. Paul, Brazil. During the exhibition, Shandong Lingong exh

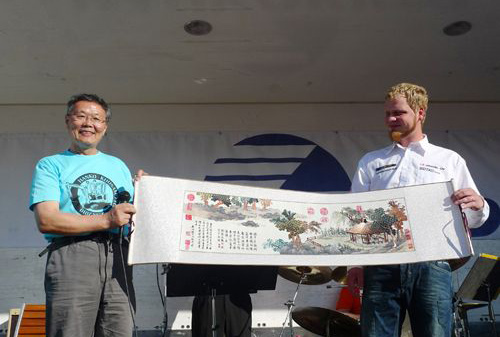

On November 7, the opening ceremony for Phase III Training of XCMG Public Welfare Project -- "Global Excellent Operator" was held in XCMG, where Li Ge, the Deputy Secreta

What is breaking force deficiency? It is when you press the brake pedal down, the loader does not slow down or stop as required. The main causes include: ① The brake system i

Copyright Notice 2002-2026 global-ce.com Construction Machinery Online. All rights reserved.

Address: Room 901, Building C, Ruipu Mansion, Hongjunying South Road No.15, Chaoyang District, Beijing.100107 P.R.China